My colleague and I recently partnered with the Environmental Protection Agency’s (EPA) GreenChill program to present a webinar about making the transition to an effective refrigerant architecture. In it, we discussed leading natural refrigerant systems, centralized and distributed options, and the controls schemes that support them. What follows are the key takeaways from that discussion, which you can view here in its entirety — last bullet under ‘Webinar Archives’.

Over the past decade, the transition toward natural refrigerants has been driven by a combination of dynamic market trends, which include: global refrigerant and food safety regulations, rapidly changing consumer expectations and corporate sustainability goals. This historic transition has helped accelerate the adoption and investigation of “future-proof” natural refrigerant architectures.

Regulatory drivers of transition to naturals

In the U.S., the California Air Resources Board (CARB) has not only fully implemented the now defunct EPA rules designed to limit the use of hydrofluorocarbon (HFC) refrigerants with high global warming potential (GWP), it is also actively working to enact more aggressive measures that would greatly impact future refrigeration system architectures. One current proposal under review would take effect in 2022 and mandate the following:

-

- Systems charged with more than 50 pounds of refrigerant must use an option that is less than 150 GWP

- New refrigerant sales with less than 50 pounds of refrigerant must use an option that is less than 1,500 GWP

But California is not alone in these initiatives; there are currently 25 states in the U.S. Climate Alliance which have vowed to follow its lead.

Since natural refrigerants are among a very small list of viable options capable of meeting the above criteria, the commercial refrigeration industry is likely to see an increase in system architectures designed to utilize natural options. These include centralized architectures for larger-charge systems and distributed (or micro-distributed) options for smaller-charged system types.

Leading natural refrigerants

When we think of natural refrigerants in commercial refrigeration, we are typically referring to R-744 (CO2 aka carbon dioxide), R-290 (refrigerant-grade propane) and R-744 (ammonia). Let’s look at their unique characteristics and how they can be effectively utilized.

CO2 has proved very effective in both low- and medium-temperature applications and is typically found in centralized systems such as secondary, cascade and transcritical booster. Having been successfully deployed in commercial and industrial applications in Europe for nearly two decades, it has made significant inroads in North America in recent years.

CO2 is not a retrofit refrigerant and is intended for use only in new systems. System designers, operators and technicians need to be aware of CO2’s unique characteristics, particularly its low critical point, high operating pressures and standing pressure (power outage) considerations. It has a GWP of 1, which puts it in an elite class of environmentally friendly options.

Propane continues to experience a global resurgence as a viable, efficient and very low-GWP refrigerant choice. Its high flammability has traditionally limited system charges to 150g, which is why today it’s found primarily in stand-alone systems that operate efficiently with a low refrigerant charge — such as integrated display cases often utilized in micro-distributed applications. In Europe and abroad, the International Electrotechnical Commission (IEC) recently raised its charge limit to 500g; the U.S. conservatively remains at 150g. Also, propane is not a retrofit option and is intended for new systems designed specifically for its use.

With its superior thermodynamic properties, ammonia was a logical first choice for early refrigeration systems. However, its toxicity requires careful adherence to safe application procedures to ensure operator safety and customer well-being. Traditionally, it has been used in industrial, process cooling, cold storage and ice rink applications. Most recently, ammonia has been introduced into commercial applications via cascade systems that utilize lower refrigerant charges and isolate the ammonia circuit away from occupied spaces.

System controls to support natural refrigerant architectures

Because of the unique properties in these emerging natural refrigerant architectures, system controls are even more essential to ensuring efficient operation, troubleshooting and servicing. Generally, the controls are loosely coupled to the refrigeration architecture, often following either a centralized or distributed approach.

However, the expanding variety of natural refrigeration systems can also pose new challenges for operators trying to maintain controls consistency or access a unified view across different systems. Here, a supervisory system — with its ability to integrate different devices into a common user interface — ensures that all stakeholders can quickly and easily evaluate each refrigeration system.

As regulations continue to evolve and natural refrigerant systems gain more acceptance, Emerson is prepared to help equipment manufacturers, system designers and end users utilize these very low-GWP alternatives in the development of efficient, user-friendly and economically viable refrigeration systems.

Six Ways to Reduce Food Waste by Tracking the Supply Chain

*Emerson’s Climate Technologies business is now a new standalone company: Copeland. Over the next...

Protect Valuable Shipments in High-Crime Areas

*Emerson’s Climate Technologies business is now a new standalone company: Copeland. Over the next...

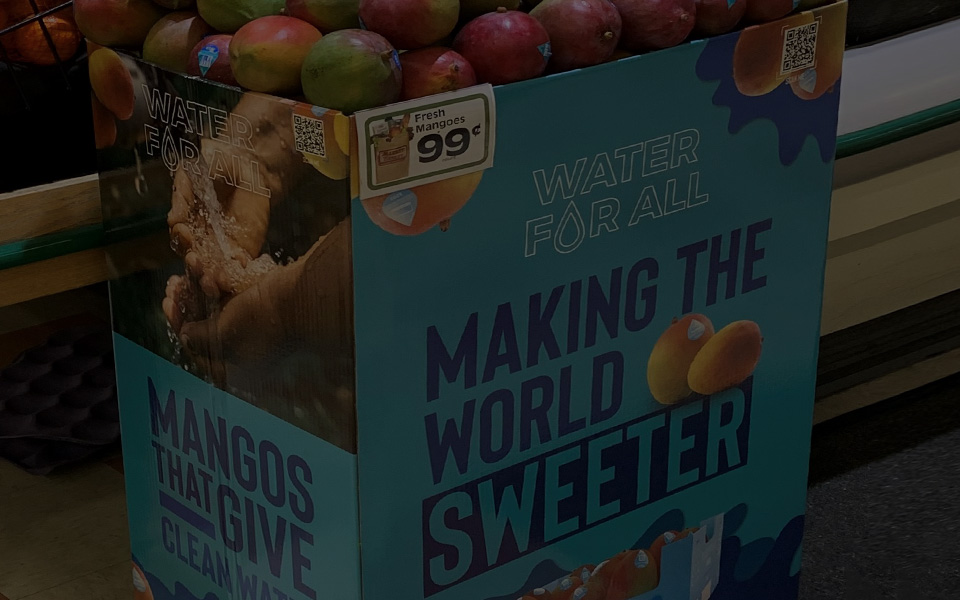

Real-time Tracking Protects Valuable Mango Cargo

*Emerson’s Climate Technologies business is now a new standalone company: Copeland. Over the next...